Understanding the Essential Role of Mineral Wool Insulation in Fire Safety

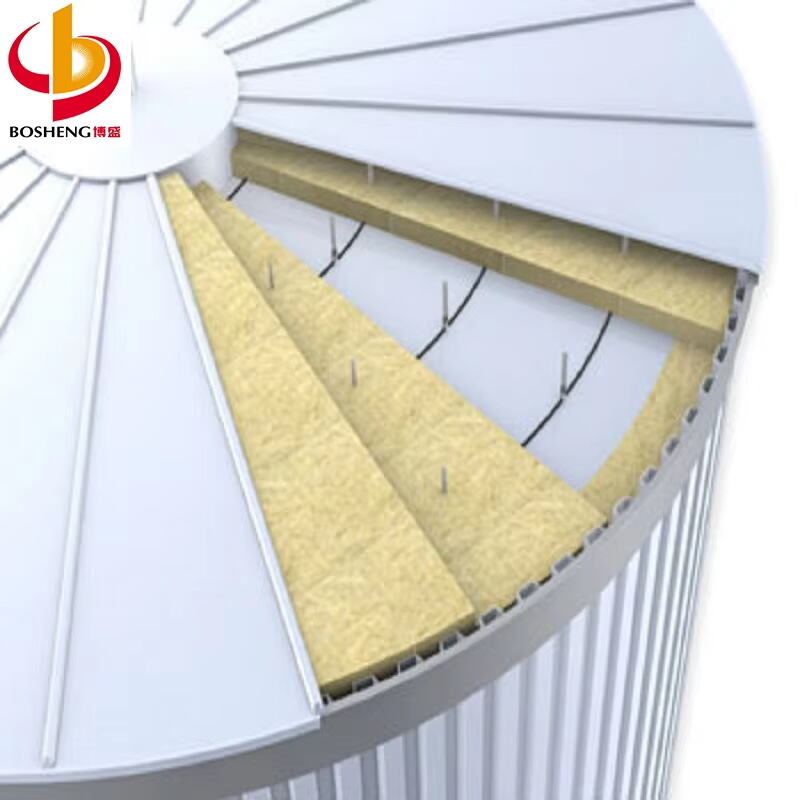

When it comes to protecting buildings and industrial facilities from the devastating effects of fire, a fireproof rock insulation blanket serves as a critical line of defense. These specially engineered materials combine superior thermal insulation properties with exceptional fire resistance, making them indispensable in modern construction and industrial applications. The innovative composition of mineral wool-based insulation provides a robust barrier against heat transfer while maintaining structural integrity even under extreme temperatures.

The foundation of these remarkable insulation solutions lies in their manufacturing process, where natural rock is melted and spun into fine fibers, creating a dense yet flexible material that excels in both thermal performance and fire protection. This unique combination of properties has made fireproof rock insulation blanket products increasingly popular across various sectors, from residential construction to heavy industry.

Core Components and Manufacturing Process

Raw Materials and Production Techniques

The production of a fireproof rock insulation blanket begins with carefully selected raw materials, primarily basalt rock and recycled slag. These materials undergo an intensive melting process at temperatures exceeding 2700°F (1500°C), transforming them into molten rock. The molten material is then spun into extremely fine fibers through a sophisticated spinning process, creating the base structure of the insulation.

Advanced binding agents are introduced during the manufacturing process to hold the fibers together, creating a stable and durable blanket structure. These binders are specially formulated to maintain their integrity under high temperatures, ensuring the insulation maintains its protective properties even during extreme fire events.

Quality Control and Testing Standards

Each fireproof rock insulation blanket undergoes rigorous quality control procedures to ensure consistent performance and reliability. Manufacturers conduct extensive testing for thermal conductivity, fire resistance, and mechanical properties. These tests typically include exposure to direct flame, measurement of thermal transmission, and evaluation of structural integrity under various temperature conditions.

International safety standards and certification requirements guide the manufacturing process, with products being tested according to ASTM E84, ASTM E136, and other relevant fire safety protocols. This ensures that every batch meets or exceeds industry requirements for fire protection and thermal insulation.

Performance Characteristics and Benefits

Thermal Resistance Properties

A high-quality fireproof rock insulation blanket demonstrates exceptional thermal resistance properties, with the ability to maintain stable temperatures across a wide range of operating conditions. The unique fiber structure creates countless air pockets that effectively slow heat transfer, resulting in thermal conductivity values as low as 0.04 W/mK at room temperature.

The thermal performance remains reliable even at elevated temperatures, making these products ideal for applications requiring continuous exposure to high-temperature environments. This consistent performance helps maintain safe operating conditions and reduces energy consumption in both industrial and commercial settings.

Fire Protection Capabilities

The non-combustible nature of rock-based insulation makes it an excellent choice for fire protection systems. When exposed to direct flame, the fireproof rock insulation blanket maintains its structural integrity and continues to provide thermal protection, unlike many synthetic alternatives that may melt or produce toxic fumes.

These materials typically achieve the highest fire rating classifications, with melting points above 2000°F (1093°C). This remarkable heat resistance enables the insulation to create an effective barrier against fire spread, potentially providing crucial additional time for evacuation and emergency response in fire situations.

Installation and Application Guidelines

Proper Installation Techniques

Successful implementation of a fireproof rock insulation blanket system requires careful attention to installation procedures. The material should be installed with minimal compression to maintain its designed thickness and thermal performance. Proper spacing and securing methods are essential to ensure complete coverage and prevent thermal bridging.

Professional installers typically use specialized fastening systems and support mechanisms designed specifically for high-temperature applications. These components must be compatible with the insulation material and rated for the intended operating temperature range to maintain system integrity.

Common Application Areas

The versatility of fireproof rock insulation blanket products makes them suitable for numerous applications across different industries. In commercial buildings, they are commonly used for fire-rated walls, floors, and ceiling assemblies. Industrial applications include equipment insulation, process vessel coverage, and pipe insulation in high-temperature environments.

Marine and offshore installations benefit from these materials' combination of fire resistance and moisture resistance. The transportation sector, including railway and automotive industries, utilizes these products for thermal management and fire protection in various components and systems.

Maintenance and Long-term Performance

Regular Inspection Protocols

To ensure continued effectiveness, regular inspections of installed fireproof rock insulation blanket systems are essential. These inspections should check for physical damage, moisture infiltration, and proper attachment to substrates. Any compromised areas should be documented and addressed promptly to maintain the system's protective capabilities.

Maintenance professionals should establish a regular inspection schedule based on the application environment and potential exposure to damaging factors. This proactive approach helps identify and address issues before they can impact the insulation's performance or safety characteristics.

Durability and Replacement Considerations

When properly installed and maintained, a fireproof rock insulation blanket can provide reliable performance for many years. However, certain factors can affect long-term durability, including exposure to excessive vibration, chemical contamination, or physical damage. Understanding these potential impacts helps in developing appropriate maintenance strategies and determining optimal replacement intervals.

Facility managers should maintain detailed records of installation dates, inspection findings, and any repairs or replacements. This documentation supports informed decision-making about system upgrades or replacements while helping to optimize maintenance budgets and ensure continuous protection.

Frequently Asked Questions

How long does a fireproof rock insulation blanket typically last?

Under normal operating conditions and with proper maintenance, a fireproof rock insulation blanket can last 20-30 years or more. However, specific environmental conditions, exposure to chemicals, or physical damage may affect its lifespan. Regular inspections help determine when replacement might be necessary.

What temperatures can rock insulation blankets withstand?

High-quality fireproof rock insulation blankets can typically withstand continuous temperatures up to 1200°F (649°C) and can survive short-term exposure to even higher temperatures, with melting points above 2000°F (1093°C). The exact temperature resistance depends on the specific product and manufacturer specifications.

Are rock insulation blankets environmentally friendly?

Yes, fireproof rock insulation blankets are considered environmentally sustainable products. They are typically made from abundant natural materials and often contain recycled content. Their long service life and energy-saving properties contribute to reduced environmental impact, and many products are fully recyclable at the end of their useful life.