Modern construction demands materials that deliver superior performance across multiple dimensions, and acoustic rock wool has emerged as a leading solution for builders seeking exceptional sound insulation and thermal efficiency. This innovative mineral fiber insulation material combines the natural properties of basalt rock with advanced manufacturing techniques to create a versatile building component that addresses the growing need for acoustic comfort in residential and commercial structures. As urban environments become increasingly dense and noise pollution continues to escalate, the importance of effective sound control in wall construction cannot be overstated. Acoustic rock wool offers architects, contractors, and property developers a reliable solution that not only mitigates unwanted sound transmission but also contributes to energy efficiency and fire safety in building design.

Superior Sound Insulation Performance

Exceptional Noise Reduction Capabilities

The primary advantage of acoustic rock wool lies in its outstanding ability to absorb and dampen sound waves across a wide frequency range. The fibrous structure of this material creates countless air pockets that trap sound energy and convert it into minimal amounts of heat through friction. Unlike traditional insulation materials, acoustic rock wool maintains consistent performance across both high and low frequency ranges, making it particularly effective for controlling everything from deep bass sounds to sharp, high-pitched noises. This comprehensive frequency response ensures that walls constructed with acoustic rock wool provide reliable protection against various types of environmental noise, including traffic sounds, industrial machinery, and neighboring activities.

Laboratory testing consistently demonstrates that acoustic rock wool can achieve sound transmission class ratings significantly higher than conventional alternatives. The material's density and fiber orientation work synergistically to create multiple barriers to sound wave propagation, resulting in substantial reductions in decibel levels between adjacent spaces. Professional acoustic engineers frequently specify acoustic rock wool for applications requiring stringent noise control standards, including recording studios, conference rooms, healthcare facilities, and residential developments located in high-noise environments.

Improved Privacy and Comfort

Beyond technical performance metrics, acoustic rock wool contributes meaningfully to occupant comfort and privacy within built environments. The enhanced sound isolation provided by this material allows for more flexible space utilization, enabling architects to design open floor plans without sacrificing acoustic separation between functional areas. Residents and workers in buildings featuring acoustic rock wool insulation report higher satisfaction levels related to noise disturbance, sleep quality, and overall environmental comfort. This improvement in acoustic comfort translates directly into increased property values and reduced tenant turnover in commercial applications.

The psychological benefits of effective noise control extend beyond mere comfort considerations. Research in environmental psychology indicates that consistent exposure to unwanted noise can increase stress levels, reduce cognitive performance, and negatively impact overall well-being. By incorporating acoustic rock wool into wall construction, builders create healthier living and working environments that support productivity and mental health for building occupants.

Thermal Efficiency and Energy Conservation

Outstanding Insulation Properties

While primarily recognized for its acoustic properties, acoustic rock wool also delivers exceptional thermal insulation performance that contributes significantly to building energy efficiency. The same fibrous structure that effectively traps sound waves also creates an excellent barrier to heat transfer, helping maintain stable interior temperatures regardless of external weather conditions. The thermal conductivity of acoustic rock wool typically ranges between 0.032 and 0.040 W/mK, placing it among the most effective insulation materials available for wall construction applications.

The mineral composition of acoustic rock wool provides inherent resistance to temperature fluctuations without degradation of insulating properties over time. Unlike organic insulation materials that may settle or compress with age, acoustic rock wool maintains its loft and thermal resistance throughout the building's lifespan. This dimensional stability ensures consistent energy performance and helps building owners achieve long-term operational cost savings through reduced heating and cooling expenses. The material's ability to function effectively across extreme temperature ranges makes it suitable for diverse climate conditions and specialized applications requiring thermal stability.

Moisture Management and Vapor Permeability

Effective moisture management represents another crucial advantage of acoustic rock wool in wall construction systems. The hydrophobic nature of properly treated acoustic rock wool prevents water absorption while maintaining vapor permeability, allowing building assemblies to regulate moisture content naturally. This balance between water resistance and breathability helps prevent condensation issues that can lead to mold growth, structural damage, and indoor air quality problems. The material's open fiber structure facilitates moisture vapor transmission while blocking liquid water penetration, creating optimal conditions for building envelope performance.

Professional building envelope consultants recognize acoustic rock wool as an effective component in moisture-resistant wall systems, particularly in humid climates or applications with high internal moisture loads. The material's ability to maintain its insulating properties even when exposed to minor moisture infiltration provides additional resilience compared to alternatives that may lose effectiveness when wet. This moisture tolerance contributes to overall building durability and reduces maintenance requirements over the structure's service life.

Fire Safety and Building Code Compliance

Non-Combustible Material Characteristics

Fire safety considerations make acoustic rock wool an increasingly popular choice for wall construction, particularly in commercial and multi-family residential applications. Manufactured from natural basalt rock and recycled steel slag, acoustic rock wool is inherently non-combustible and maintains its structural integrity at temperatures exceeding 1000°C. This exceptional fire resistance provides valuable time for occupant evacuation and firefighting efforts while helping prevent fire spread between building compartments. The material does not produce toxic gases when exposed to flames, contributing to safer evacuation conditions during emergency situations.

Building codes worldwide increasingly emphasize fire-resistant construction materials, and acoustic rock wool consistently meets or exceeds these stringent requirements. The material typically achieves Class A fire ratings according to ASTM standards and similar international testing protocols. This superior fire performance allows architects and engineers to specify acoustic rock wool with confidence in applications requiring enhanced fire safety, including high-rise buildings, healthcare facilities, educational institutions, and industrial structures where fire protection is paramount.

Regulatory Compliance and Certification

The widespread acceptance of acoustic rock wool by building officials and code enforcement agencies stems from extensive testing and certification by recognized standards organizations. Products meeting international standards for acoustic rock wool undergo rigorous evaluation for fire performance, structural integrity, environmental impact, and long-term durability. These certifications provide architects, contractors, and building owners with documentation necessary for permit approval and project completion, streamlining the construction process while ensuring code compliance.

Environmental certifications for acoustic rock wool products address growing sustainability requirements in modern construction. Many manufacturers offer formaldehyde-free acoustic rock wool options that contribute to healthy indoor environments while meeting green building standards such as LEED, BREEAM, and similar rating systems. These certifications support project teams pursuing sustainable construction goals while maintaining high performance standards for acoustic and thermal control.

Installation Versatility and Construction Benefits

Adaptable Installation Methods

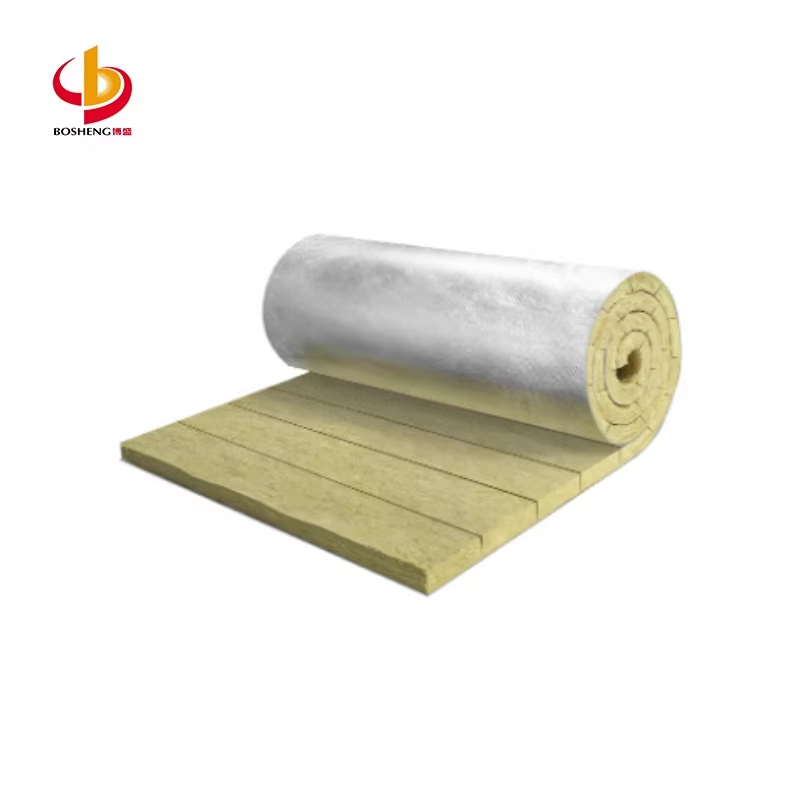

The physical characteristics of acoustic rock wool facilitate efficient installation across various wall construction methods, from traditional framed systems to contemporary prefabricated assemblies. The material can be supplied in multiple formats, including batts, boards, blankets, and loose-fill applications, allowing contractors to select the most appropriate product form for specific project requirements. This versatility enables acoustic rock wool integration into both new construction and renovation projects without requiring specialized installation equipment or extensive modification of existing construction practices.

Professional installers appreciate the dimensional stability and workability of acoustic rock wool during construction activities. The material maintains its shape during handling and installation while conforming effectively to irregular cavities and penetrations. Unlike some alternative insulation materials, acoustic rock wool can be compressed temporarily during installation without permanent loss of performance characteristics, simplifying placement in tight spaces or around building services. The non-irritating properties of properly manufactured acoustic rock wool also contribute to improved working conditions for installation crews.

Long-Term Performance and Durability

The exceptional longevity of acoustic rock wool represents a significant economic advantage for building owners and developers. Independent testing demonstrates that properly installed acoustic rock wool maintains its acoustic and thermal performance characteristics for decades without significant degradation. The inorganic nature of the material provides resistance to biological growth, pest infiltration, and chemical degradation that can affect organic insulation alternatives. This durability translates into reduced maintenance requirements and sustained performance throughout the building's operational life.

Life cycle assessments consistently show that acoustic rock wool provides superior long-term value when total cost of ownership is considered. While initial material costs may be higher than some alternatives, the combination of energy savings, reduced maintenance requirements, and extended service life creates positive return on investment for most applications. The material's recyclable content and potential for end-of-life recycling also align with circular economy principles increasingly important in sustainable construction practices.

Environmental Impact and Sustainability

Sustainable Manufacturing Processes

The production of acoustic rock wool incorporates significant percentages of recycled content, particularly from steel industry byproducts that would otherwise require disposal in landfills. This recycling process transforms industrial waste into high-performance building materials, contributing to circular economy objectives while reducing environmental impact. Manufacturing facilities for acoustic rock wool increasingly utilize renewable energy sources and implement closed-loop water systems to minimize resource consumption and environmental footprint during production processes.

Advanced manufacturing techniques for acoustic rock wool have evolved to eliminate formaldehyde-based binders in favor of bio-based alternatives that reduce volatile organic compound emissions. These improvements in production chemistry create healthier indoor environments while maintaining the superior performance characteristics that make acoustic rock wool attractive for construction applications. The commitment to environmental responsibility in manufacturing processes aligns with growing demand for sustainable building materials that support green construction initiatives.

Energy Efficiency Contributions

The thermal insulation properties of acoustic rock wool contribute significantly to building energy efficiency by reducing heating and cooling loads throughout the structure's operational life. This energy conservation translates directly into reduced greenhouse gas emissions and decreased demand on electrical grid infrastructure. Studies conducted by energy research organizations demonstrate that buildings incorporating high-performance insulation materials like acoustic rock wool can achieve energy consumption reductions of 20-40% compared to structures with conventional insulation systems.

The dual functionality of acoustic rock wool as both thermal and acoustic insulation eliminates the need for separate material systems, reducing overall material consumption and construction waste. This consolidation of functions supports lean construction principles while maintaining superior performance across multiple building envelope requirements. The reduced material usage and associated transportation impacts contribute to lower embodied energy and carbon footprint for construction projects specifying acoustic rock wool systems.

FAQ

What makes acoustic rock wool different from standard mineral wool insulation

Acoustic rock wool is specifically engineered to optimize sound absorption characteristics while maintaining excellent thermal insulation properties. The manufacturing process creates a more open fiber structure with enhanced acoustic performance compared to standard mineral wool products. Additionally, acoustic rock wool typically features specialized binder systems and fiber orientations designed to maximize noise reduction across broader frequency ranges than conventional mineral wool insulation materials.

How does acoustic rock wool perform in high-moisture environments

Properly manufactured acoustic rock wool exhibits excellent moisture resistance due to hydrophobic treatment applied during production. The material maintains its insulating and acoustic properties even when exposed to elevated humidity levels or minor water infiltration. The open fiber structure allows vapor permeability while preventing liquid water absorption, making acoustic rock wool suitable for applications in bathrooms, basements, and other high-moisture areas when properly detailed within the wall assembly.

Can acoustic rock wool be used in both residential and commercial construction

Yes, acoustic rock wool is extensively used in both residential and commercial construction applications. The material meets building code requirements across various occupancy types and can be specified for everything from single-family homes to high-rise office buildings. Different product densities and configurations are available to meet specific performance requirements for each application type, from basic residential noise control to stringent commercial acoustic standards.

What installation considerations are important for maximum acoustic rock wool performance

Proper installation requires complete cavity filling without compression or gaps that could compromise acoustic performance. Installers should ensure tight fits around electrical boxes, pipes, and other penetrations while maintaining the material's loft. Sealing air leakage paths in the wall assembly is equally important, as even small gaps can significantly reduce the acoustic effectiveness of the insulation system. Professional installation following manufacturer guidelines ensures optimal performance of acoustic rock wool systems.

Table of Contents

- Superior Sound Insulation Performance

- Thermal Efficiency and Energy Conservation

- Fire Safety and Building Code Compliance

- Installation Versatility and Construction Benefits

- Environmental Impact and Sustainability

-

FAQ

- What makes acoustic rock wool different from standard mineral wool insulation

- How does acoustic rock wool perform in high-moisture environments

- Can acoustic rock wool be used in both residential and commercial construction

- What installation considerations are important for maximum acoustic rock wool performance