External wall insulation rock wool has become an essential component in modern building construction, offering superior thermal performance and fire resistance for commercial and residential structures. This mineral-based insulation material provides architects, contractors, and building owners with reliable solutions for enhancing energy efficiency while meeting stringent building codes and regulations. The growing demand for sustainable construction practices has positioned external wall insulation rock wool as a preferred choice among industry professionals seeking long-term performance and environmental benefits.

Understanding External Wall Insulation Rock Wool Technology

Manufacturing Process and Composition

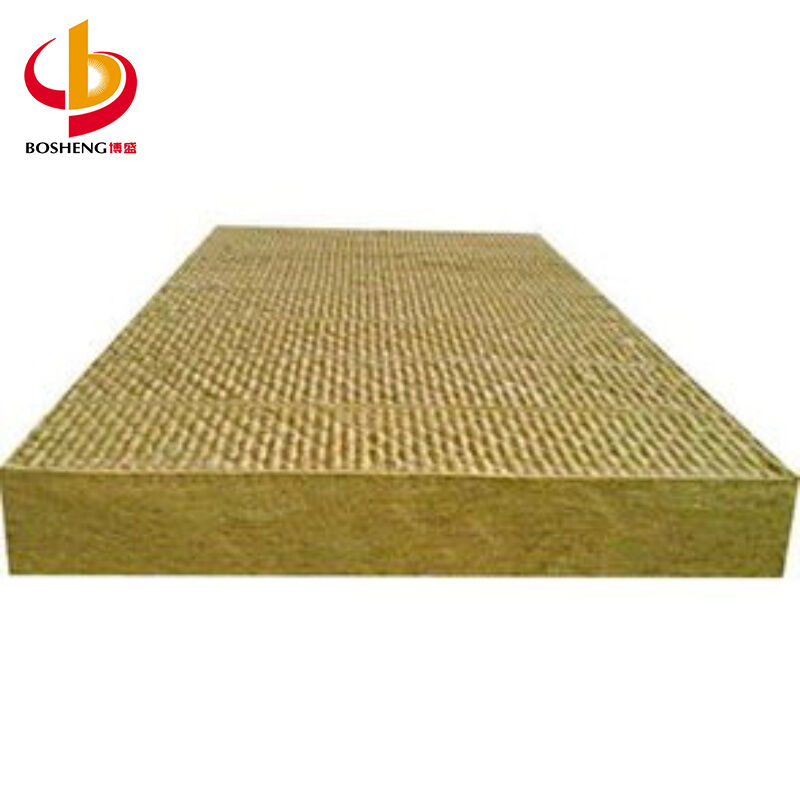

External wall insulation rock wool is manufactured through a sophisticated process that transforms natural basalt rock and recycled steel slag into high-performance insulation fibers. The raw materials are heated to temperatures exceeding 1500°C, creating molten rock that is spun into fine fibers using centrifugal force. These fibers are then bound together with organic resins to form rigid boards or flexible batts suitable for various external wall applications.

The resulting product exhibits exceptional thermal properties, with thermal conductivity values typically ranging from 0.032 to 0.042 W/mK. This low thermal conductivity ensures effective heat transfer resistance, making external wall insulation rock wool an ideal choice for reducing energy consumption in buildings. The manufacturing process also incorporates quality control measures to ensure consistent density and dimensional stability across all product batches.

Physical Properties and Performance Characteristics

External wall insulation rock wool demonstrates remarkable physical properties that contribute to its widespread adoption in construction applications. The material maintains its structural integrity across a wide temperature range, from -200°C to 750°C, without significant degradation or performance loss. This temperature stability ensures long-term reliability in diverse climatic conditions and building environments.

The vapor permeability of external wall insulation rock wool allows moisture to pass through the material while maintaining thermal performance. This breathability prevents condensation buildup within wall assemblies, reducing the risk of mold growth and structural damage. Additionally, the non-combustible nature of rock wool provides inherent fire resistance, contributing to overall building safety and compliance with fire protection standards.

Comparative Analysis of Rock Wool Solutions

Thermal Performance Comparison

When evaluating different external wall insulation rock wool products, thermal performance stands as the primary consideration for building professionals. High-quality rock wool insulation typically achieves R-values ranging from R-3.0 to R-4.3 per inch of thickness, depending on the specific product formulation and manufacturing techniques employed. These values represent superior thermal resistance compared to many traditional insulation materials.

The thermal bridge reduction capabilities of external wall insulation rock wool contribute significantly to overall building energy performance. By creating a continuous insulation layer on the exterior of structural elements, rock wool systems minimize heat transfer through thermal bridges, resulting in more consistent interior temperatures and reduced heating and cooling costs. This continuous insulation approach can improve whole-wall R-values by 20-40% compared to cavity-only insulation systems.

Durability and Longevity Assessment

The durability of external wall insulation rock wool systems directly impacts long-term building performance and maintenance costs. Quality rock wool products demonstrate exceptional resistance to physical degradation, maintaining their thermal properties for decades without significant performance decline. Laboratory testing and field studies indicate that properly installed external wall insulation rock wool can perform effectively for 50+ years.

Environmental factors such as freeze-thaw cycles, UV exposure, and moisture infiltration pose potential challenges to insulation longevity. However, external wall insulation rock wool exhibits superior resistance to these environmental stressors compared to organic insulation materials. The inorganic nature of rock wool prevents biological degradation and ensures dimensional stability throughout the service life of the building.

Installation Methods and Best Practices

Mechanical Fastening Systems

Mechanical fastening represents one of the most reliable methods for securing external wall insulation rock wool to building substrates. This installation approach utilizes specialized fasteners designed to penetrate through the insulation and anchor securely into the structural wall system. The fastener selection depends on substrate material, insulation thickness, and local wind load requirements.

Proper fastener spacing and pattern distribution ensure uniform load transfer and prevent thermal bridging through the insulation layer. Industry best practices recommend fastener densities ranging from 4-8 fasteners per square meter, depending on building height, exposure conditions, and local building codes. The use of thermal break washers or caps minimizes heat transfer through fastener penetrations, maintaining the thermal integrity of the external wall insulation rock wool system.

Adhesive Application Techniques

Adhesive bonding provides an alternative or complementary installation method for external wall insulation rock wool systems. High-performance adhesives specifically formulated for mineral wool applications create strong bonds with various substrate materials, including concrete, masonry, and metal cladding systems. The adhesive application requires careful surface preparation and environmental considerations to achieve optimal bond strength.

The combination of mechanical fasteners and adhesive bonding, known as the dual-attachment method, offers enhanced system reliability and performance. This hybrid approach distributes loads more evenly across the insulation surface while providing redundant attachment mechanisms. External wall insulation rock wool systems using dual-attachment methods demonstrate superior wind uplift resistance and long-term stability in challenging environmental conditions.

Performance Benefits in Building Applications

Energy Efficiency Enhancement

External wall insulation rock wool systems deliver significant energy efficiency improvements through continuous thermal protection and thermal bridge mitigation. Buildings utilizing comprehensive external wall insulation rock wool can achieve energy savings of 30-50% compared to structures with conventional cavity insulation alone. These savings translate to reduced operational costs and improved occupant comfort throughout the building lifecycle.

The thermal mass benefits of external wall insulation rock wool contribute to improved indoor temperature stability and reduced peak heating and cooling loads. By positioning the insulation on the exterior side of thermal mass elements, the system allows interior wall materials to moderate temperature fluctuations naturally. This thermal mass optimization reduces HVAC system cycling and enhances overall building energy performance.

Acoustic Performance Advantages

Beyond thermal benefits, external wall insulation rock wool provides excellent acoustic insulation properties that enhance occupant comfort and productivity. The fibrous structure of rock wool effectively absorbs sound energy across a broad frequency range, reducing both airborne and impact noise transmission through building envelopes. Sound transmission class ratings for external wall insulation rock wool systems typically range from STC 45-60, depending on system configuration and wall assembly details.

The acoustic benefits of external wall insulation rock wool prove particularly valuable in urban environments with high ambient noise levels. Commercial and residential buildings incorporating comprehensive rock wool insulation systems experience significant reductions in exterior noise intrusion, creating more comfortable interior environments. This acoustic performance enhancement adds value to building occupancy and can contribute to improved productivity in commercial applications.

Environmental Impact and Sustainability

Life Cycle Assessment Considerations

Environmental responsibility drives increasing interest in the sustainability profile of external wall insulation rock wool products. Life cycle assessment studies demonstrate that rock wool insulation systems provide net positive environmental benefits through energy savings that far exceed the environmental impact of manufacturing and installation. The payback period for embodied carbon in external wall insulation rock wool typically ranges from 6-18 months of building operation.

The manufacturing process for external wall insulation rock wool incorporates significant recycled content, with many products containing 70% or more post-industrial and post-consumer recycled materials. This high recycled content reduces the demand for virgin raw materials while diverting waste from landfills. Additionally, rock wool products maintain their performance characteristics through multiple recycling cycles, supporting circular economy principles in construction.

Indoor Air Quality Impact

Indoor environmental quality considerations make external wall insulation rock wool an attractive choice for health-conscious building projects. The inorganic composition of rock wool eliminates concerns about volatile organic compound emissions commonly associated with organic insulation materials. This low-emission characteristic contributes to healthier indoor environments and supports green building certification requirements.

The moisture management properties of external wall insulation rock wool contribute to improved indoor air quality by preventing conditions conducive to mold and mildew growth. The vapor-permeable nature of rock wool allows moisture to migrate naturally through wall assemblies while maintaining thermal performance. This moisture management capability reduces the risk of indoor air quality issues related to biological contaminants.

Cost Analysis and Economic Considerations

Initial Investment Assessment

The initial cost of external wall insulation rock wool systems requires careful evaluation within the context of long-term building performance and operational savings. While premium rock wool products may carry higher upfront costs compared to basic insulation materials, the superior performance characteristics justify the investment through enhanced durability, energy efficiency, and reduced maintenance requirements.

Material costs for external wall insulation rock wool vary based on product specifications, thickness requirements, and project scale. Bulk purchasing opportunities and long-term supply agreements can provide cost advantages for large-scale construction projects. The total installed cost includes material, labor, and accessory components, with typical installation costs ranging from $8-15 per square foot for complete external insulation systems.

Long-term Value Proposition

The economic benefits of external wall insulation rock wool extend well beyond initial installation costs through reduced energy consumption, lower maintenance requirements, and enhanced building durability. Energy cost savings typically range from 25-40% annually, providing measurable return on investment throughout the building lifecycle. These savings compound over time, often resulting in full cost recovery within 5-10 years of installation.

Property value enhancement represents an additional economic benefit of external wall insulation rock wool systems. Buildings with comprehensive external insulation command premium rental rates and sale prices due to reduced operating costs and improved occupant comfort. The enhanced building envelope performance also contributes to higher building ratings in energy efficiency certification programs, further increasing market value and competitive advantage.

Quality Standards and Certification Requirements

Industry Standards Compliance

External wall insulation rock wool products must comply with various industry standards and testing protocols to ensure consistent performance and reliability. ASTM International standards provide comprehensive testing methods for thermal conductivity, compressive strength, dimensional stability, and fire resistance properties. Compliance with these standards ensures that external wall insulation rock wool products meet minimum performance thresholds for commercial and residential applications.

International Organization for Standardization protocols establish global benchmarks for external wall insulation rock wool quality and performance characteristics. These standards facilitate international trade and ensure compatibility between different manufacturer products. Building professionals can specify external wall insulation rock wool products with confidence, knowing that certified materials meet established performance criteria regardless of manufacturing origin.

Third-party Verification Programs

Independent testing and certification programs provide additional assurance of external wall insulation rock wool quality and performance claims. Organizations such as Underwriters Laboratories, Factory Mutual, and similar testing bodies conduct comprehensive evaluations of insulation products under controlled laboratory conditions. These third-party verifications validate manufacturer performance data and provide building professionals with reliable product information.

Environmental product declarations and sustainability certifications add another layer of verification for external wall insulation rock wool products. These declarations provide transparent information about environmental impacts, recycled content, and end-of-life considerations. Building projects pursuing green building certifications often require these environmental verifications to earn sustainability credits and demonstrate environmental responsibility.

FAQ

What factors determine the optimal thickness for external wall insulation rock wool systems

The optimal thickness for external wall insulation rock wool depends on climate zone requirements, building energy targets, and economic considerations. Generally, thicker insulation provides better thermal performance, but the law of diminishing returns applies beyond certain thicknesses. Most commercial applications utilize 2-6 inches of external wall insulation rock wool, while high-performance buildings may specify up to 8 inches or more. Building energy modeling can help determine the most cost-effective thickness for specific projects.

How does external wall insulation rock wool perform in extreme weather conditions

External wall insulation rock wool demonstrates excellent performance in extreme weather conditions due to its inorganic composition and stable physical properties. The material maintains thermal performance from -200°C to 750°C without degradation, making it suitable for all climate zones. Rock wool also exhibits superior wind uplift resistance and dimensional stability during freeze-thaw cycles, ensuring long-term performance reliability in challenging environmental conditions.

What maintenance requirements apply to external wall insulation rock wool systems

External wall insulation rock wool systems require minimal maintenance throughout their service life due to the inherent durability of the material. Regular visual inspections of cladding systems and weather barriers help identify potential issues before they affect insulation performance. The rock wool itself does not degrade or settle over time, eliminating the need for replacement or supplementation that may be required with other insulation materials.

Can external wall insulation rock wool be recycled at the end of building life

Yes, external wall insulation rock wool can be recycled through specialized processing facilities that separate the mineral fibers from binding agents. The recycled rock wool can be reprocessed into new insulation products or used in other applications such as growing media for horticulture. This recyclability supports circular economy principles and reduces the environmental impact of building demolition and renovation projects.

Table of Contents

- Understanding External Wall Insulation Rock Wool Technology

- Comparative Analysis of Rock Wool Solutions

- Installation Methods and Best Practices

- Performance Benefits in Building Applications

- Environmental Impact and Sustainability

- Cost Analysis and Economic Considerations

- Quality Standards and Certification Requirements

-

FAQ

- What factors determine the optimal thickness for external wall insulation rock wool systems

- How does external wall insulation rock wool perform in extreme weather conditions

- What maintenance requirements apply to external wall insulation rock wool systems

- Can external wall insulation rock wool be recycled at the end of building life