Sound control has become increasingly critical in modern construction projects, whether for residential, commercial, or industrial applications. Acoustic rock wool stands as one of the most effective materials for achieving superior noise reduction while simultaneously providing thermal insulation benefits. This mineral-based insulation material offers exceptional sound absorption properties that make it an ideal solution for walls, ceilings, floors, and mechanical equipment enclosures where noise control is paramount.

Professional installation of acoustic rock wool requires careful attention to detail, proper material handling, and adherence to established building codes and safety protocols. The success of any acoustic treatment project depends heavily on understanding the material properties, selecting appropriate densities, and implementing correct installation techniques that maximize the sound absorption coefficient while maintaining structural integrity.

Understanding Acoustic Rock Wool Properties

Material Composition and Sound Absorption Mechanics

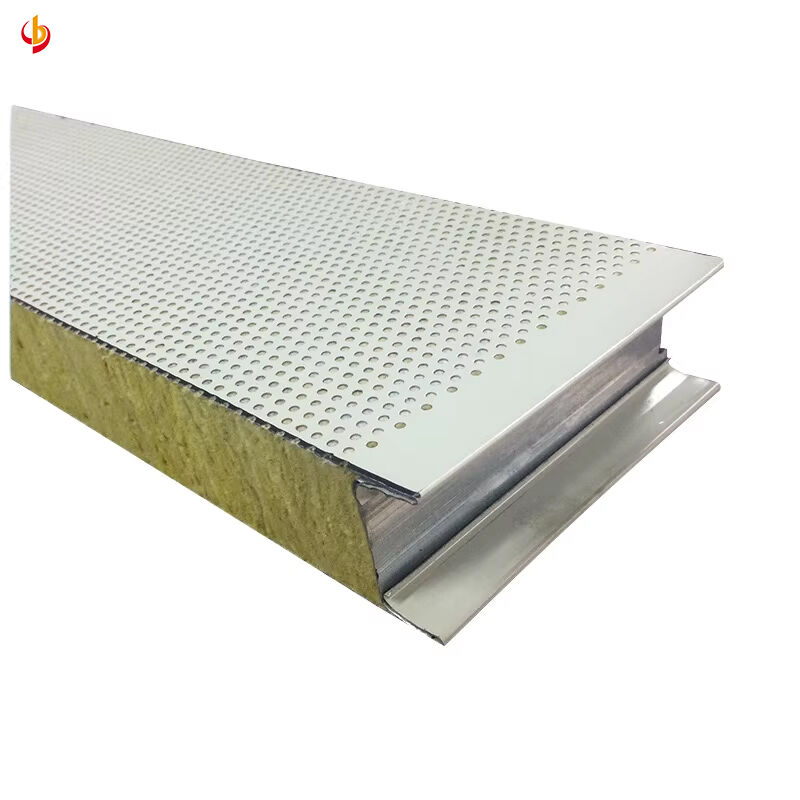

Acoustic rock wool is manufactured from natural basalt rock that undergoes high-temperature melting and spinning processes to create fibrous insulation material. The resulting product features an open-cell structure with interconnected air pockets that trap sound waves and convert acoustic energy into minimal heat through friction. This mechanism makes acoustic rock wool particularly effective at absorbing mid to high-frequency sounds that are commonly problematic in building environments.

The density of acoustic rock wool significantly impacts its performance characteristics, with typical ranges spanning from 32 kg/m³ to 120 kg/m³ depending on the intended application. Higher density materials provide enhanced low-frequency absorption and improved fire resistance, while lower density options offer easier handling and installation flexibility. Understanding these density variations helps determine the most suitable product for specific acoustic requirements and installation conditions.

Thermal and Fire Performance Benefits

Beyond acoustic properties, rock wool insulation delivers exceptional thermal performance with R-values typically ranging from R-3.0 to R-4.2 per inch of thickness. This dual functionality makes acoustic rock wool an economical choice for projects requiring both sound control and energy efficiency improvements. The material maintains its insulating properties across a wide temperature range, making it suitable for applications in extreme climates.

Fire resistance represents another significant advantage of acoustic rock wool, with melting points exceeding 1000°C and non-combustible classification ratings. This inherent fire safety makes the material particularly valuable in commercial and industrial installations where building codes mandate specific fire-resistance requirements. The material does not contribute to flame spread and produces minimal smoke when exposed to extreme heat.

Pre-Installation Planning and Safety Preparation

Site Assessment and Measurement Requirements

Proper installation begins with comprehensive site assessment to identify acoustic problem areas, structural constraints, and environmental conditions that may affect material performance. Accurate measurements of wall cavities, ceiling spaces, and equipment enclosures ensure appropriate material quantities and prevent installation delays. Consider factors such as moisture levels, temperature variations, and potential settling that could impact long-term acoustic rock wool effectiveness.

Documentation of existing mechanical systems, electrical conduits, and plumbing components helps plan installation sequences that minimize interference and maintain proper clearances. Identify areas requiring special attention such as penetrations, irregular spaces, and locations where continuous coverage is critical for optimal acoustic performance. This planning phase prevents costly mistakes and ensures efficient installation workflows.

Safety Equipment and Personal Protection

Working with acoustic rock wool requires appropriate personal protective equipment including disposable coveralls, safety glasses, dust masks or respirators, and work gloves to prevent skin irritation and inhalation of mineral fibers. Ensure adequate ventilation in work areas and consider using portable fans or extraction systems when installing in enclosed spaces with limited air circulation.

Establish proper material handling procedures that minimize fiber release during cutting, fitting, and installation activities. Use sharp utility knives or specialized insulation cutting tools to achieve clean cuts that reduce airborne particles. Maintain organized work areas with proper disposal containers for waste materials and protective equipment to prevent cross-contamination of clean areas.

Installation Techniques for Maximum Effectiveness

Wall Cavity Installation Methods

Wall cavity installation of acoustic rock wool requires careful attention to fit and compression levels to achieve optimal performance. Cut material pieces slightly oversized to ensure snug fit against framing members without excessive compression that could reduce acoustic effectiveness. Maintain material thickness at manufacturer specifications, as over-compression significantly reduces sound absorption capabilities and thermal performance.

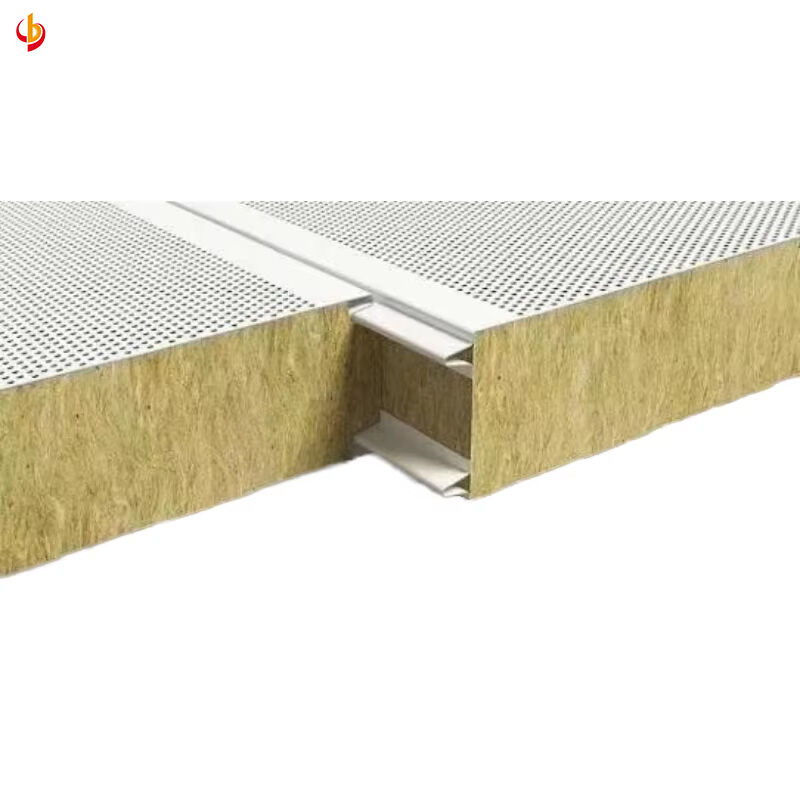

Install acoustic rock wool in continuous layers without gaps or voids that could create acoustic bridges allowing sound transmission. Pay particular attention to areas around electrical outlets, switches, and penetrations where careful cutting and fitting prevents thermal and acoustic short circuits. Use friction-fit installation techniques that hold material in place without additional fasteners that could compromise integrity.

For double-wall assemblies requiring enhanced acoustic performance, stagger joints between layers and maintain proper spacing between parallel surfaces to prevent resonance issues. Consider using acoustic rock wool with integrated facings or vapor barriers when moisture control requirements necessitate additional protection layers.

Ceiling and Overhead Installation Procedures

Ceiling installation presents unique challenges requiring temporary support systems to hold acoustic rock wool in position during installation. Use wire mesh, acoustic hangers, or specialized clips designed for mineral wool applications to prevent sagging and maintain proper contact with ceiling structures. Ensure support systems distribute load evenly across material surfaces to prevent compression or tearing.

Install acoustic rock wool above suspended ceiling systems by placing material on top of ceiling tiles or between ceiling grid members depending on acoustic requirements and accessibility constraints. Maintain proper clearances around light fixtures, HVAC components, and other ceiling-mounted equipment while ensuring continuous coverage in adjacent areas for optimal sound control performance.

Equipment Enclosure and Mechanical System Applications

HVAC Equipment Noise Control

Mechanical equipment rooms require specialized acoustic rock wool installation techniques to address both airborne and structure-borne noise transmission. Install material around equipment enclosures with sufficient thickness to attenuate low-frequency noise while providing access for maintenance activities. Consider removable panels or access doors lined with acoustic rock wool for equipment that requires regular service.

Ductwork applications benefit from external wrapping with acoustic rock wool secured using appropriate fastening systems that prevent material displacement while allowing thermal expansion movement. Maintain consistent coverage without gaps or thin spots that could compromise acoustic performance. Pay special attention to duct connections, transitions, and equipment interfaces where noise transmission is often most problematic.

Industrial Equipment Sound Dampening

Large industrial equipment installations require acoustic rock wool systems designed to handle high sound pressure levels and potentially harsh environmental conditions. Design enclosure systems that accommodate equipment vibration, thermal cycling, and maintenance requirements while providing effective noise control. Consider using higher density acoustic rock wool materials for applications with severe noise challenges or space constraints.

Implement multi-layer acoustic rock wool systems for equipment producing broad-frequency noise spectrums, with varying densities optimized for different frequency ranges. Ensure proper air circulation around equipment while maintaining acoustic integrity through strategic placement of inlet and outlet openings lined with appropriate acoustic treatment materials.

Quality Control and Performance Verification

Installation Inspection Procedures

Systematic inspection of acoustic rock wool installation ensures compliance with design specifications and identifies potential performance issues before project completion. Verify material thickness, density, and coverage consistency throughout all installed areas using appropriate measuring tools and documentation procedures. Check for gaps, compression, or damaged sections that could compromise acoustic effectiveness.

Document installation procedures, material specifications, and any deviations from original design requirements for future reference and warranty purposes. Photograph critical installation details and maintain records of material batch numbers, installation dates, and personnel involved in various project phases. This documentation proves valuable for troubleshooting performance issues and planning future maintenance activities.

Performance Testing and Validation

Post-installation acoustic testing validates the effectiveness of acoustic rock wool systems and identifies areas requiring adjustment or additional treatment. Use calibrated sound level meters and frequency analyzers to measure noise reduction across relevant frequency ranges and compare results to design targets and building code requirements.

Conduct testing under realistic operating conditions with equipment running at normal loads to assess real-world performance rather than theoretical calculations. Document baseline measurements before acoustic rock wool installation and compare post-installation results to quantify actual noise reduction achievements and validate installation success.

Maintenance and Long-Term Performance

Preventive Maintenance Requirements

Acoustic rock wool installations require minimal maintenance when properly installed and protected from moisture infiltration or physical damage. Establish inspection schedules that include visual examination of material condition, checking for displacement or compression, and monitoring for signs of moisture intrusion that could compromise performance or create mold growth conditions.

Address any identified issues promptly to prevent minor problems from developing into major performance compromises or health concerns. Replace damaged sections with matching acoustic rock wool materials and installation techniques to maintain system integrity and acoustic performance consistency throughout the treated areas.

Performance Monitoring and Upgrades

Long-term performance monitoring helps identify gradual changes in acoustic effectiveness and determines when system upgrades or modifications may be beneficial. Changes in building use, equipment additions, or updated noise control requirements may necessitate additional acoustic rock wool installation or system modifications to maintain desired performance levels.

Consider emerging acoustic rock wool technologies and improved installation techniques that could enhance existing system performance during planned maintenance or renovation activities. Advanced materials with enhanced acoustic properties or easier installation characteristics may provide cost-effective upgrade opportunities for older installations.

FAQ

What thickness of acoustic rock wool provides optimal noise reduction performance

Optimal acoustic rock wool thickness depends on the specific frequency range requiring treatment and available installation space. For general building applications, 2-4 inch thickness typically provides effective noise reduction across most problematic frequencies. Thicker installations of 6-8 inches offer enhanced low-frequency absorption but require adequate cavity depth and proper support systems to prevent compression or sagging issues.

Can acoustic rock wool be installed in high-moisture environments

Acoustic rock wool can be installed in moderate moisture environments when properly protected with appropriate vapor barriers and moisture management systems. However, direct water contact or prolonged high humidity exposure can reduce acoustic performance and create potential health concerns. Install proper ventilation and moisture control measures in areas such as mechanical rooms, basements, or exterior wall applications where moisture infiltration risks exist.

How does acoustic rock wool compare to other sound absorption materials

Acoustic rock wool offers superior fire resistance, thermal performance, and durability compared to many alternative sound absorption materials such as fiberglass or foam products. The material maintains its acoustic properties across wider temperature ranges and provides better long-term stability without significant performance degradation. However, initial costs may be higher than some alternatives, though lifecycle value often favors acoustic rock wool due to longevity and multi-functional benefits.

What special considerations apply to acoustic rock wool installation around electrical components

Electrical component areas require careful acoustic rock wool installation to maintain proper clearances and prevent interference with electrical systems while achieving effective sound control. Cut material precisely around outlet boxes, switches, and conduits to eliminate gaps without creating compression against electrical components. Consider fire-stopping requirements and electrical code compliance when installing acoustic rock wool in areas with significant electrical infrastructure concentrations.

Table of Contents

- Understanding Acoustic Rock Wool Properties

- Pre-Installation Planning and Safety Preparation

- Installation Techniques for Maximum Effectiveness

- Equipment Enclosure and Mechanical System Applications

- Quality Control and Performance Verification

- Maintenance and Long-Term Performance

-

FAQ

- What thickness of acoustic rock wool provides optimal noise reduction performance

- Can acoustic rock wool be installed in high-moisture environments

- How does acoustic rock wool compare to other sound absorption materials

- What special considerations apply to acoustic rock wool installation around electrical components