Understanding the Revolutionary Impact of Mineral Fiber Insulation in Modern Construction

The construction industry has witnessed remarkable evolution in insulation materials over the decades, with rock wool rolls emerging as a standout solution for both residential and commercial projects. These versatile mineral fiber products, crafted from molten rock spun into fibers, have revolutionized how we approach building insulation. Their growing popularity stems from an impressive combination of thermal performance, fire resistance, and environmental benefits that collectively contribute to safer, more efficient buildings.

As construction professionals and property owners increasingly prioritize sustainable and high-performance building materials, rock wool rolls have become a cornerstone of modern construction practices. This natural mineral-based insulation solution addresses multiple challenges faced in contemporary building projects, from energy efficiency requirements to stringent safety regulations.

Essential Properties and Performance Features

Superior Thermal Insulation Capabilities

Rock wool rolls demonstrate exceptional thermal resistance properties, effectively reducing heat transfer between indoor and outdoor environments. The unique fiber structure creates countless tiny air pockets that trap heat, resulting in outstanding R-values that maintain consistent indoor temperatures year-round. This thermal efficiency translates to significantly reduced energy consumption for heating and cooling systems.

The thermal performance of rock wool rolls remains stable throughout their lifetime, unlike some alternative materials that may compress or settle over time. This long-term reliability ensures that buildings maintain their energy efficiency for decades, making them a cost-effective choice for construction projects.

Acoustic Excellence and Sound Control

One of the most compelling advantages of rock wool rolls lies in their superior acoustic properties. The dense fiber structure effectively absorbs sound waves, reducing noise transmission between rooms and from external sources. This makes them particularly valuable in multi-residential buildings, commercial spaces, and properties near high-traffic areas.

The sound absorption capabilities of rock wool rolls extend across a wide range of frequencies, providing comprehensive noise control solutions. Whether installed in walls, floors, or ceilings, these materials significantly contribute to creating quieter, more comfortable indoor environments.

Safety and Environmental Considerations

Fire Resistance and Building Safety

Rock wool rolls boast impressive fire-resistant properties, with the ability to withstand temperatures up to 1000°C. This natural fire resistance stems from their mineral composition, providing crucial additional time for building evacuation during fire emergencies. The non-combustible nature of rock wool rolls makes them an essential component in fire-safe building design.

Beyond fire resistance, these materials do not emit toxic fumes when exposed to heat, further enhancing their safety profile. This characteristic has made rock wool rolls particularly popular in commercial and industrial construction where fire safety standards are exceptionally stringent.

Environmental Sustainability and Impact

The environmental credentials of rock wool rolls are particularly noteworthy in today's eco-conscious construction landscape. Manufactured primarily from abundant natural rock, these materials have a lower environmental impact compared to many synthetic alternatives. The production process can incorporate recycled materials, contributing to circular economy principles.

Furthermore, rock wool rolls are fully recyclable at the end of their life cycle, reducing construction waste. Their durability and longevity mean fewer replacements are needed over time, minimizing the overall environmental impact of building maintenance and renovation.

Installation and Practical Applications

Versatility in Construction Projects

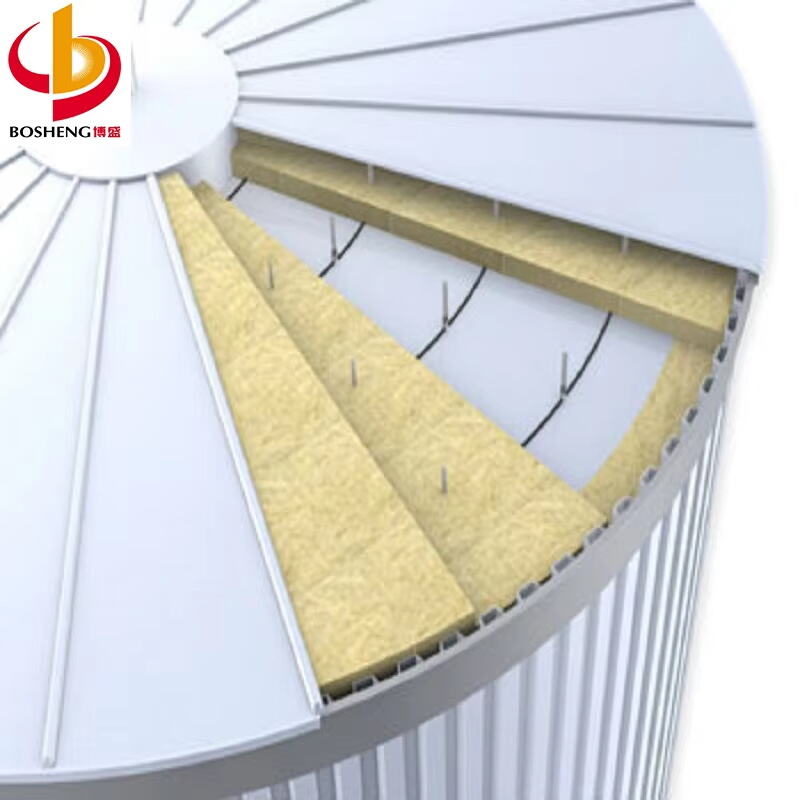

Rock wool rolls demonstrate remarkable versatility across various construction applications. Their flexibility and adaptability make them suitable for installation in walls, roofs, floors, and even around complex architectural features. The material can be easily cut to size and fits snugly between standard building frameworks, ensuring comprehensive coverage without gaps.

The adaptability of rock wool rolls extends to both new construction and renovation projects. Their compatibility with different building systems and materials makes them a practical choice for diverse construction scenarios, from residential homes to large commercial complexes.

Installation Efficiency and Best Practices

The installation of rock wool rolls is relatively straightforward, though attention to detail is crucial for optimal performance. The material's dimensional stability ensures it maintains its shape during and after installation, while its friction fit properties help prevent slumping or settling over time. Professional installers appreciate the material's workability and the minimal specialized tools required for installation.

Proper handling and installation techniques are essential to maximize the benefits of rock wool rolls. This includes wearing appropriate protective equipment, ensuring proper compression during installation, and maintaining continuous insulation coverage to prevent thermal bridges.

Cost Considerations and Long-term Value

Initial Investment and Return Analysis

While the initial cost of rock wool rolls may be higher than some alternative insulation materials, their long-term value proposition is compelling. The durability and performance stability of these materials mean they maintain their effectiveness for decades, reducing the need for replacement or maintenance. Additionally, their energy-saving properties contribute to lower utility costs throughout the building's lifetime.

The multi-functional benefits of rock wool rolls – combining thermal insulation, acoustic control, and fire safety – often make them more cost-effective than installing multiple separate solutions. This consolidation of benefits can result in significant cost savings in both materials and labor.

Maintenance and Longevity Benefits

Rock wool rolls require minimal maintenance once properly installed. Their moisture-resistant properties help prevent mold and mildew growth, while their dimensional stability ensures they maintain their effectiveness without settling or compressing over time. This reliability translates to reduced maintenance costs and fewer future replacements.

The material's resistance to deterioration and its ability to maintain its properties over decades make it a wise investment for long-term construction projects. Property owners can expect consistent performance throughout the building's lifetime, contributing to sustained energy efficiency and comfort.

Frequently Asked Questions

How long do rock wool rolls typically last in a building?

Rock wool rolls can maintain their performance properties for the entire lifetime of a building, which typically exceeds 50 years. Their mineral composition ensures they remain stable and effective without degradation, provided they are properly installed and protected from external damage.

Can rock wool rolls be used in both cold and hot climates?

Yes, rock wool rolls perform excellently in all climate conditions. Their thermal properties work effectively to keep heat in during cold weather and out during hot weather. The material's performance remains consistent across a wide range of temperatures, making it suitable for use in any geographical location.

Are rock wool rolls safe for residential use?

Rock wool rolls are completely safe for residential use when properly installed. The material is non-toxic, does not off-gas, and meets strict safety standards for building materials. While protective equipment is recommended during installation, once in place, rock wool rolls pose no health risks to building occupants.